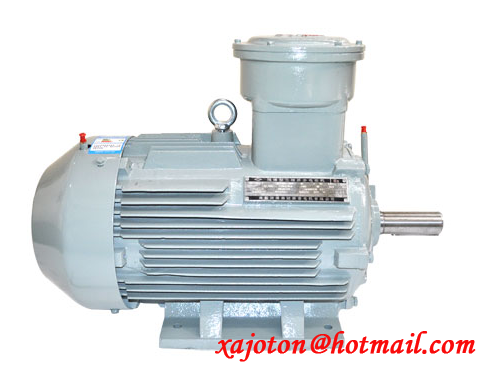

YKK three-phase asynchronous motor

- brand Nanyang

- model

- describe

YKK three-phase asynchronous motor

YKK three-phase asynchronous motor

YKK series (6kV) high-voltage three-phase asynchronous motor (frame size 355) is a series optimized by our company on the basis of introducing domestic and foreign high-voltage motor manufacturing technology, combined with the current advanced design and manufacturing experience of high-voltage three-phase asynchronous motor. product.

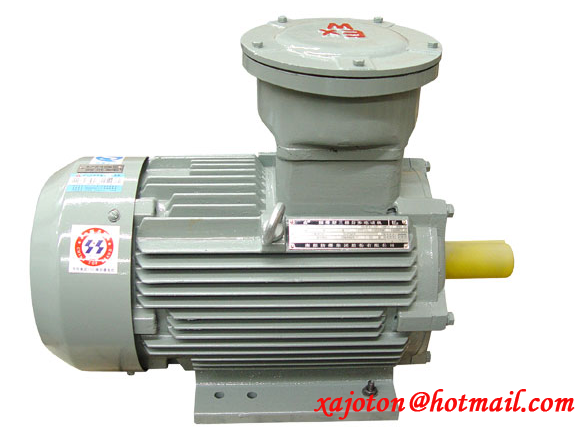

This series of products adopts modern new technology and new materials. The materials are well-selected and well-made, with high efficiency, energy saving and noise.

Low sound, low vibration, light weight, reliable performance, convenient installation and maintenance.

This series of motors meets the national standard 68755 "Rotating Motor Ratings and Performance", industry standard JB/T7593

"Y series high-voltage three-phase asynchronous motor technical conditions (frame size 355)", JB/T10315.2 "YKK, YKK-W series

Column high-voltage three-phase asynchronous motor technical conditions (355) and international standard I EC34, the mechanical dimensions and tolerances of each part meet the corresponding national standards and international standards.

The protection level of this series of motors is I P54~1:1l P55. Cooling method is I C01, l C61 1, installation method

For lMB3, the corresponding protection type, cooling method and installation method can also be made according to user requirements.

This series of motors can also be made into wet tropical, dry tropical, outdoor and outdoor resistant to moderate corrosion and outdoor wet tropical.

This series of motors can be used to drive a variety of general machinery, such as compressors, pumps, crushers, cutting machine tools, transportation machinery and other mechanical equipment, in the mining, machinery industry, petrochemical industry, power plants and other industrial and mining enterprises use.

The main technical parameters

Structure description

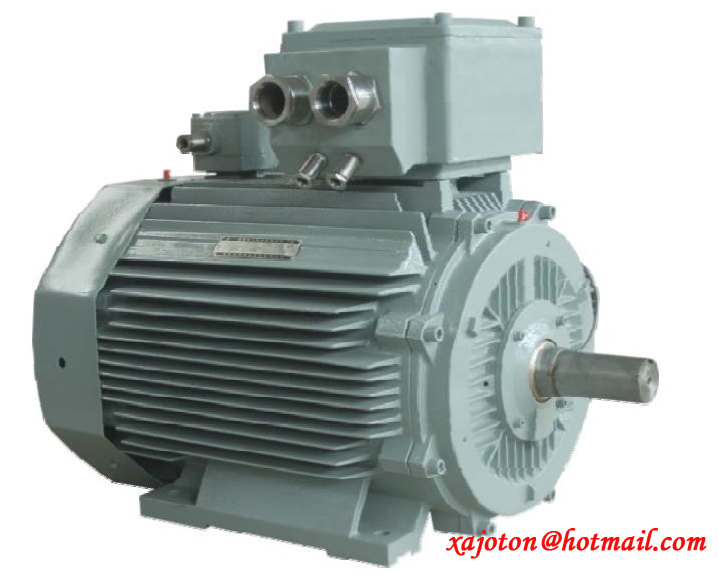

This series of motors adopts the internationally popular box structure, and the components such as the base and the end cover are welded with steel plates, which are light in weight and good in steel. Remove the top cover or cooler. It can be observed or touched inside the motor for easy installation and maintenance.

The Y series is the basic series, and the protection grade is IP23. On this basis, some components can be added to easily derive different cooling methods and protection methods.

The junction box is sealed and has a degree of protection of lP54 or IP55. Generally installed on the right side of the motor (from the shaft extension end), it can also be installed on the left side according to the user's needs. The incoming cable L of the box faces downward, and there are separate grounding terminals inside and outside the box.

The stator adopts three kinds of external pressure structure: hoisting, sliding in and pressing. The stator winding adopts F-class insulating material, using VPl vacuum pressure dipping technology, using magnetic wedges, reliable fixing and binding at the ends, and excellent insulation performance. Reliable, high mechanical strength, strong moisture resistance, making the motor run safely and reliably.

The rotor adopts a squirrel cage structure, which is dynamically balanced by high-precision verification, and the motor runs smoothly and the vibration is small. The motor is provided with a cylindrical shaft extension, and can also be made into a double shaft extension according to the needs of the user.

According to the motor power and speed, the bearing adopts two types of rolling bearing and sliding bearing. The rolling bearing is provided with non-stop injection and oil discharge device. It can realize the continuous operation of the motor. Regularly add grease to maintain and maintain the motor.

The sliding bearing is an end-cover spherical sliding bearing, which adopts pressure oil lubrication or oil ring self-lubrication or compound lubrication, and measures to prevent shaft current generation are adopted.

Conditions of Use

Ambient air temperature: 15 ° C ~ +40 ° C

Altitude: no more than 1000 meters

Working system: S1

Environmental conditions: indoor, outdoor (w), wet tropical (TH), outdoor wet tropical (THW)

上一篇:YB2 flameproof three-phase asynchronous motor

下一篇:没有了