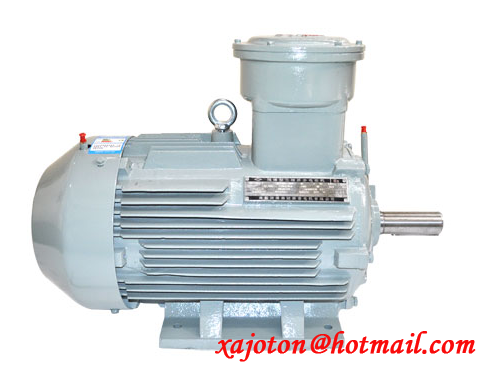

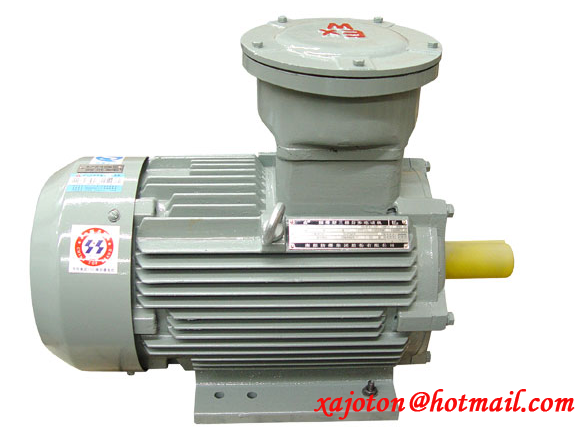

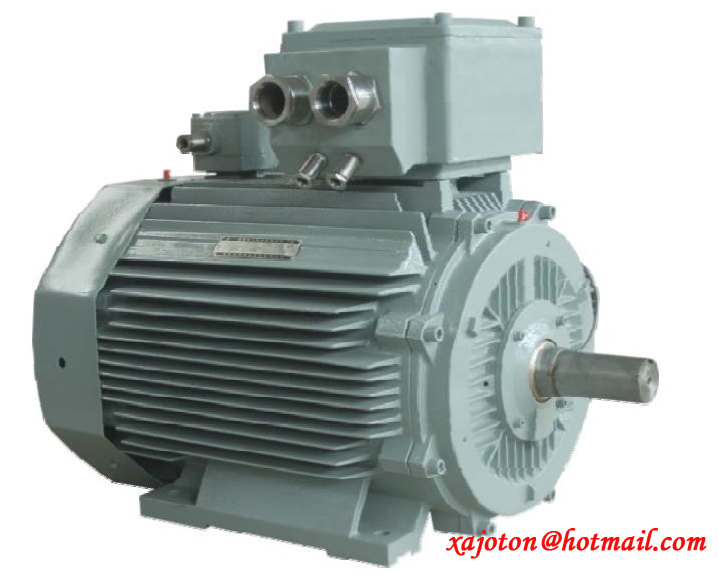

YB2 flameproof three-phase asynchronous motor

- brand Nanyang

- model

- describe

YB2 flameproof three-phase asynchronous motor

YB2 flameproof three-phase asynchronous motor

Rated voltage: 380V, 660V, 400V, 415V, 380/660V, 660/1140V

Rated frequency: 50Hz

Rated power: 0.12kW-315KW

Protection level: IP54, IP55, WIP55

Working system: S1

Insulation class: F

YB2 series flameproof three-phase asynchronous motor is the basic series of explosion-proof motor of our company YB series. This series of motors has small size, light weight, beautiful appearance, safe and reliable operation, long service life, excellent performance, convenient installation and maintenance. .

The power class and installation dimensions of this series of motors comply with the International Electrotechnical Commission (IEC) standards, and their correspondence is the same as the German DIN42673 standard, which is conducive to the matching of export equipment and spare parts for imported equipment.

The explosion-proof performance of this series of motors complies with GB3836.1-2000 "Electrical equipment for explosive gas atmospheres Part 1: General requirements" and GB3836.2-2000 "Electrical equipment for explosive gas atmospheres Part 2: Explosion-proof type d" The regulations are also in accordance with IEC79-7, BS4683 and EN50018, and are made into flameproof type. The explosion-proof marks are Ex dI, Ex dIIAT4, Ex dIIBT4, which are suitable for use in places where explosive gas mixtures are present.

Ex dI is suitable for underground coal mine non-mining face environment in the presence of explosive mixtures of methane or coal dust

Ex dIIAT4 is suitable for use in plant Class II, Class A, temperature groups in the presence of explosive gas mixtures of Groups T1, T2, T3 and T4.

Ex dIIBT4 is suitable for use in the Class II, Class B, plant, temperature range for the presence of explosive gas mixtures in the T1, T2, T3 and T4 groups.

Based on the YB2 basic series motor, it can also be made into YB2-W outdoor type, YB2-WF1 outdoor medium anti-corrosion type and other climatic conditions.

Structure description

2.1 The flameproof structure of the motor has Ex dI, Ex dIIAT4, Ex dIIBT4.

2.2 Motor main body protection class IP55.

2.3 The cooling method of the motor is IC411.

2.4 The motor insulation grade is F grade, and the stator winding has a large temperature rise margin and a long service life.

2.5 The motor has a cylindrical shaft extension, which is driven by a coupling or gear.

2.6 The stator winding of the motor is made of high-strength enamelled round copper wire and processed by vacuum pressure dipping to form a complete whole. The winding and insulation have good electrical, mechanical, moisture-proof performance and thermal stability.

2.7 The rotor of the motor adopts cast aluminum structure, and the rotor is checked by dynamic balance. The motor runs smoothly, the vibration is small, and the noise is low.

2.8 Motor stator and rotor punching plate adopt high-magnetic, low-loss high-quality electrical silicon steel sheet, which has low motor loss and high efficiency.

2.9 Motor bearings use low-vibration and low-noise bearings for motors, double-sided sealed bearings with frame size 160 and below, and wave spring washers at the shaft extensions to properly restrain the vibration generated by the motor when the motor is running. Noise, frame size No. 180 and above adopts inner and outer cover structure, and the bearing ring is axially fixed at the bearing part, effectively preventing the axial movement of the motor rotor.

In order to use the motor safely and reliably, the motor bearing structure of the frame number 180 and above is equipped with an oil filling device, the motor with the frame number 250 and above, and the position of the bearing temperature monitoring sensor element is reserved.

2.10 Motor fan and hood: The motor with frame number 280 and below adopts anti-static plastic fan, which has small moment of inertia and low loss. The frame size is 315 and above. The cast aluminum or steel plate welding fan is light in weight and high in strength. The series of fans and shafts are keyed for reliable operation. The windshield is a steel plate structure, and the maximum ventilation area is obtained under the premise of preventing intrusion of a certain size of foreign objects, so that the wind path is smooth.

上一篇:YBX3 high efficiency flameproof three-phase asynchronous mot